Paper Aluminum: The Revolutionary Packaging Technology

Paper aluminum is a cutting-edge technology revolutionizing the packaging industry. It combines the properties of paper and aluminum to create a material that is both eco-friendly and efficient for protecting products during shipping.

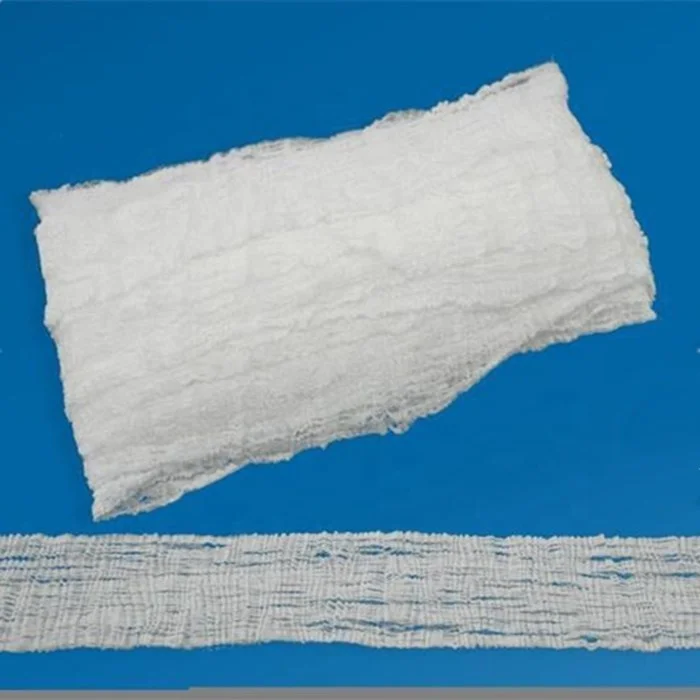

Paper aluminum is made by sandwiching a thin layer of aluminum foil between two paper layers. The paper used is typically sourced from sustainably managed forests, making it a renewable and biodegradable alternative to plastic and Styrofoam.

This innovative packaging material biodegrades naturally over time, reducing waste and pollution in the environment. It is suitable for packaging a wide range of products, including food, electronics, and cosmetics, offering companies the ability to brand and print directly onto the packaging.

Paper aluminum helps maintain the freshness and taste of food by providing an airtight and moisture-resistant barrier. It is a safer and more sustainable option compared to plastic and Styrofoam, contributing to a reduced carbon footprint in the packaging industry.

The lightweight nature of paper aluminum reduces energy consumption during production and transportation, further lowering carbon emissions. As consumer demand for sustainable packaging grows, paper aluminum is poised to become a preferred choice for both individuals and businesses.

Fancyco has been paper aluminum in expanding into over 80 countries and regions across the globe. In 2015, Fancyco was able to establish itself as the No. one brand in hygiene and sticker papers in Nigeria and Uganda. This demonstrated our ability to enter markets and to lead them with high-quality products and superior service.

paper aluminum established in 2004 was established in 2004 and has earned a reputation as an industry leader in the world of packaging and printing supplies over the past 20 years. As a gold-certified supplier on Alibaba We achieved the first step in our commitment towards the highest quality and customer satisfaction.

Fancyco has over a quarter of a century of expertise in RD and is dedicated to technological advancement We manage a provincial level technology center backed by an experienced RD team of more than paper aluminum years of experience This expertise enables us to create cutting-edge products and solutions that are able to meet the changing requirements of our global clients

The factory established in paper aluminum boasts a large production capacity that includes 500+ sets of equipment and over 300 molds We focus on strict quality control in all of our manufacturing processes to ensure top quality machines that are in compliance with the highest specifications Every step from CAD-CAM to powder coating to professional assembly is performed with a high degree of precision to guarantee quality and reliability of the products